Micro and Nano Lab

Advanced method of composite machining

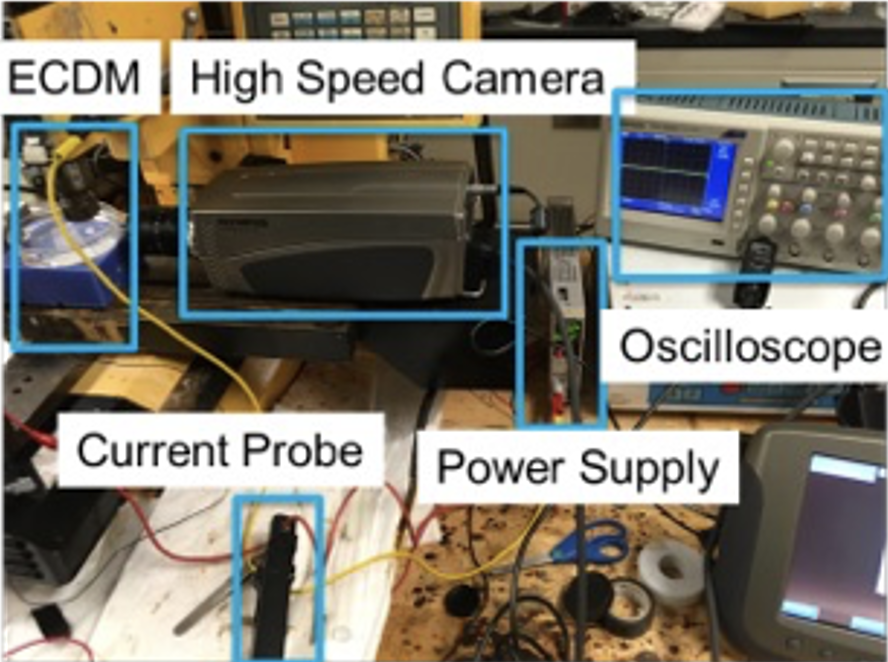

Resin reinforced fiber composites are well known today for their lightweight and high strength. However, the machining of the material is a challenge as the high strength causing loss of tool wear, and the reinforcing epoxy would be challenging to the machine with thermal machining methods. In the UC Micro and Nano Manufacturing Laboratory electrical machining methods are provided to machining carbon fibers composites. Electrochemical discharge machining (ECDM) illustrated here is a unique machining process that utilizes an electric current to machine conductive and non-conductive material by this method. In this project, the student will use an existing pulse ECDM setup shown below to investigate the machining of different fiber composite materials (e.g., carbon fiber, fiberglass).

Learning opportunities for students

As this research is multidisciplinary in nature, it offers a tremendous opportunity for undergraduate students to be exposed to interdisciplinary research. The project will also introduce students to the various of academic research starting from literature review to report preparation. The experimentation involved will offer hands-on experience in research for the students. Students will learn about the theory behind the ECDM process and understand the working of the pulse ECDM. The students will also be encouraged to present the work at either a conference and/or prepare a paper for journal publication.

Scaling up of Electrochemical Additive Manufacturing

Electrochemical additive manufacturing (ECAM) is a novel, emerging method of additive manufacturing that uses localized electrochemical deposition (localized metal plating) between a tool and a substrate when they are sufficiently close together in a metal plating bath. A current spike through the electrochemical circuit occurs when the tool and deposit touch, indicating that the metal deposit has grown between the tool-substrate gap enough to touch the tool. When this feedback is combined with a positioning and control system, this becomes an additive manufacturing (3d printing) process capable of depositing 3d metal parts. View the video.

Concept of ECAM executed in a multi-electrode fashion

The goal of this project is for the student to extend the existing one-electrode system into a multi-electrode system capable of depositing complex, overhanging shapes. The concept is illustrated in Figure 2. The work of the project will involve the design and construction of the physical electrode array, as well as programming and testing of its operation.

An example concept of preliminary shapes built in one direction (vertical or Z) using a 3 x 2 array is shown in Figure 3. However, after a successful build of basic shapes, the students are encouraged to stretch to the limits of their imagination - what shapes can be built using different-sized arrays, arrays with different electrode orientations, and incorporation of the X and Y build directions?

Learning opportunities for students

Participating in this project will expose the undergraduate student to hands-on, interdisciplinary research. Students will build have the opportunity to build rare and valuable skills in studying physical phenomena from first-principles, experimentation characterization methods, analog hardware design, and/or modeling of the process at the atomic scale.

Demonstration of electrode activation for sample shapes built using a 3 x 2 electrode array

Fundamental research skills will be covered including literature review, presentation, and report writing. The undergraduate student will also be encouraged to begin building a professional body of research work by presenting the work at either a conference and/or preparing![]() a paper for journal publication.

a paper for journal publication.

Final deliverables will include

- Experimental proof-of-concept on student-determined CAD files, beginning with simple shapes and progressing to the most complex shapes that the students can figure out how to build

- Description on how the each array is constructed and its associated build algorithm works

- Documentation on the problem-solving process to generate each array and algorithm

Students will gain exposure to

- Providing new knowledge on an emerging manufacturing technique

- Conducting a literature review

- Hands-on experiments with an electrochemical setup and hardware

- Coding algorithms

- Problem solving

- An excellent opportunity to exercise your initiative, creativity, critical thinking, scientific judgment, scientific knowledge, problem solving, and teamwork skills

Simulation and experimentation of deep-hole machining process

Electrochemical discharge machining (ECDM) is unique for the complex machining method that can machining non-conducive material such as glass with an electric current. The machining ongoing inside a hole is hard to characterize and therefore, simulation models are created for deep-hole analysis.

In this project, the student will use ANSYS fluent which is a common software for fluid-flow analysis to simulate the ECDM conditions in a deep machined hole. Then the student will use the optimize parameter they achieve in the simulation to create the deepest hole in glass with ECDM in our lab.

Learning opportunities for students

As this research is multidisciplinary in nature, it offers a tremendous opportunity for undergraduate students to be exposed to interdisciplinary research. The project will also introduce students to various academic research starting from literature review to report preparation.

Student will learn to use ANSYS to create their own simulation model. The experimentation involved will offer hands-on experience in research for the students. Students will learn about the theory behind the ECDM process and understand deep hole ECDM. The students will also be encouraged to present the work at either a conference and/or prepare a paper for journal publication.

Wire EDM

When you hear the word “machining”, usually you imagine conventional machining methods in a machine shop that use cutting tools: lathes, drills, mills, and so on. Electro discharge machining (EDM) is a nontraditional method of machining that uses the principle of spark erosion to remove material. EDM can take the form of die-sinking EDM (analogous to a drill press, as seen in Figure 2 and Figure 3), or wire EDM (analogous to a band-saw, as seen in Figure 4). This goal of this project is for the student to create a functioning wire EDM system.

The working mechanism behind EDM, whether it is operated in a die-sinking or wire method, is achieved by placing two electrodes, a tool and a substrate, in a dielectric fluid. When a high voltage is applied to the electrodes and they are sufficiently close, the dielectric breaks down and a spark occurs across the fluid, causing machining to occur, as illustrated in Figure 3.

The laboratory has all the starting materials needed for a working EDM system:

- Tool, substrate, and dielectric materials

- Three linear stepper motor stages for a 3-axis stage

- Power supplies

- Input/output boards of several brands to allow for computer sensing and control of hardware (Arduino, National Instruments, Raspberry Pi)

- Electronic circuit components such as wires, transistors, capacitors, alligator clips, resistors, and so on

- Troubleshooting tools including a multimeter, oscilloscope, and current probe

The task of the student is to automate a working wire EDM system from the materials available in the laboratory. The wire EDM configuration is shown in Figure 4, where the “tool” is a wire moving through a set of spools and able to cut the entire cross-section of the substrate.

Learning opportunities for students

Participating in this project will expose the undergraduate student to hands-on, interdisciplinary research. Students will build have the opportunity to build rare and valuable skills in studying physical phenomena from first-principles, experimentation characterization methods, analog hardware design, and/or modeling of the process at the atomic scale. Fundamental research skills will be covered including literature review, presentation, and report writing. The undergraduate student will also be encouraged to begin building a professional body of research work by presenting the work at either a conference and/or preparing a paper for journal publication.

Final deliverables will include:

- Experimental proof-of-concept on student-determined CAD files

- Documentation on the problem-solving process

Students will gain exposure to

- Providing new knowledge on an emerging manufacturing technique

- Conducting a literature review

- Hands-on experiments with the electro-discharge setup and hardware

- Coding algorithms

- Problem solving

- An excellent opportunity to exercise your initiative, creativity, critical thinking, scientific judgment, scientific knowledge, problem solving, and teamwork skills

Director

Murali Sundaram

Professor, CEAS - Mechanical Eng

631 Rhodes Hall