Electro Discharge Machining

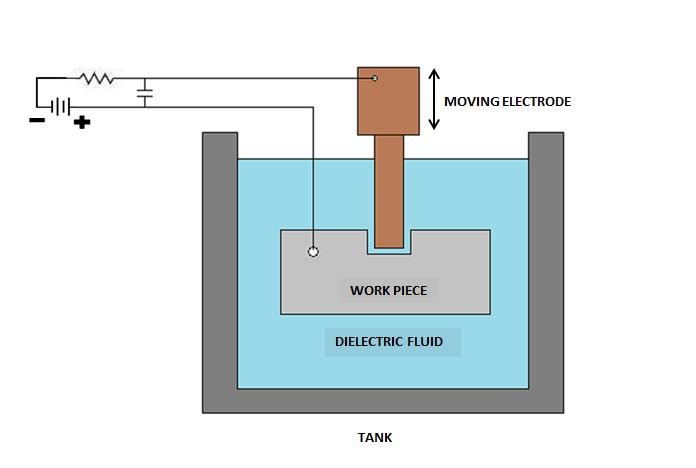

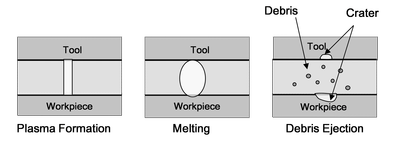

Electrical Discharge Machining (EDM) is a non-contact thermal machining process capable of machining conductive and semi-conductive materials regardless of their hardness. Conversion of electrical energy to thermal energy through repeated occurrence of sparks between the tool and the workpiece immersed in a dielectric medium and separated by a small distance (spark gap) results in the material removal from workpiece as well as tool by melting , evaporation and spalling in some special cases. The material removed is the major source of debris particles. The common dielectric fluids used are kerosene, paraffin, and light hydrocarbon oils. A necessary condition for producing a discharge is the ionization of the dielectric medium and splitting up its molecules into ions and electrons (i.e., formation of plasma). A schematic sketch of EDM and the material removal mechanism are shown in Figure 1 and 2 respectively.

One of our ongoing research activities in the field of Micro EDM is the study of mechanism of material removal in the process. Theoretical and experimental studies are being conducted to understand the influence of various process parameters for an effective process.

Figure 1: Schematic Diagram of EDM Process

Figure 2: Material Removal Mechanism in EDM Process