Molecular Modelling & Molecular Dynamics

The research interests of Molecular dynamics group at UCMAN (University of Cincinnati micro and nano manufacturing laboratory) are in field of micro and nano nontraditional manufacturing. The group primarily focuses on developing a fundamental understanding of these manufacturing techniques using Molecular Dynamic Simulations (MDS). Unlike macro scale manufacturing most of the micro and nano scale manufacturing process mechanisms are impossible to be examined by naked eye and thus provide a huge barrier in understanding the exact process mechanisms and influence of process parameters on these mechanisms. While theory could provide an insight to the mechanism, the very nature of these processes demand real time computation beyond the reach of most of the theoretical methods and hence fall into the domain of computer simulations. Molecular dynamics group at UCMAN uses MDS techniques to visualize the fundamental process mechanisms by computing forces on all the atoms in the simulation cell at every time step (time integration) by predefined potentials (atomic interaction parameters).

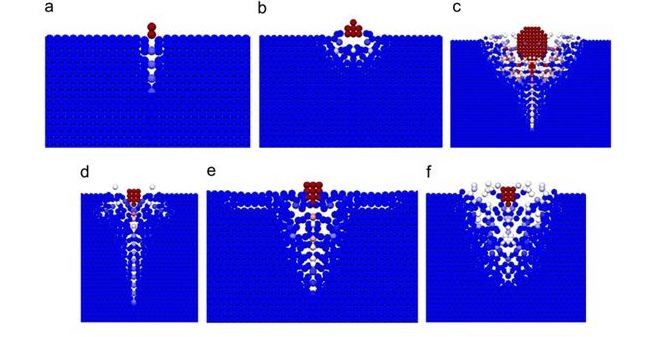

Previous work at UCMAN includes development of a novel nano manufacturing technique VANILA process (Vibration Assisted Nano-Impact-Machining by Loose Abrasives). Furthermore this novel manufacturing technique was analyzed using MDS to study tool wear, material removal rate, the effect of impact velocity, particle size and angle of impact of abrasive grain on the work piece. The results thus obtained are experimentally validated and published.

Figure 1 Modes of material removal during the VNILS process obtained through MD simulation (a) Cone crack (b) Plastic deformation (c) Plastic deformation + Cone crack (d) Plastic deformation + Cone crack + Lateral crack (e) Cone crack + Lateral crack and (f) Transition